This is an archived article that was published on sltrib.com in 2012, and information in the article may be outdated. It is provided only for personal research purposes and may not be reprinted.

Promontory • Utah aeronautical contractor Alliant Techsystems says it has streamlined its process of making booster rockets, while also acknowledging Tuesday that it will have to lay off more workers early next year.

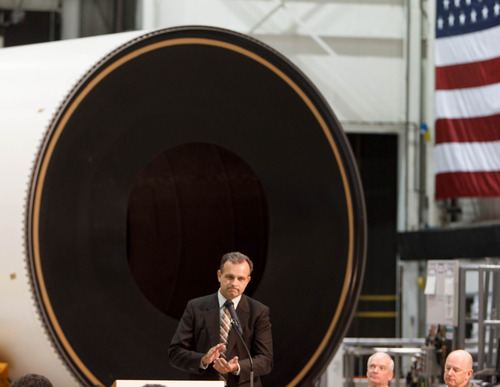

The company will be reducing the number of its employees by an untold number in February in response to its anticipated workload, said Charlie Precourt, ATK's vice president and general manager for the Space Launch System (SLS).

"We don't know the exact number," he said. "We're striving every day to not make it be any, but we're anticipating a small number."

Precourt said the layoffs would be companywide in the rocket propulsion teams at Utah's three ATK plants — in Promontory near Brigham City, and in Magna and Clearfield. ATK not only makes rocket boosters for NASA, but has a weapons division for the U.S. military and a sporting division that produces ammunition and shooting accessories for sports shooting and law enforcement. The operations for the latter are largely based outside Utah. The company employs about 2,500 workers in Utah, and about 600 work on the NASA SLS, which is powered by ATK's solid rocket boosters.

Although Precourt would not say how many job losses there will be, he insisted they are not part of the stream of layoffs that occurred in the past 3 ½ years, which were largely related to the end of the space shuttle program and resulted in more than 2,000 employees being cut. He added that ATK employees already know about the pending layoffs.

Precourt also said the upcoming reduction was not a part of the company's recent effort to streamline its manufacturing of rocket boosters, a process it calls "value stream mapping."

With the help of NASA, ATK was able to identify areas where there were redundancies and made upgrades to its manufacturing and testing to improve the time and cost of making its boosters for its space launch system. NASA's SLS will launch future rockets into space for human exploration. It can be used to launch rockets for both crew and cargo missions.

With the approximately 400 changes made to the process, which took a year to implement, the company can save as much as 46 percent of the assembly time, as well as millions of dollars in projected costs.

Although the process is reducing costs and eliminating unnecessary steps in producing the boosters, Precourt said that does not mean the company is taking shortcuts. He said the steps have not affected the safety of the rockets or increased their risks.

"We have a lot of opportunity to test and validate [their safety]," he said.

Although NASA would not say whether the changes would make ATK more competitive for future contracts, "what it does do is show ATK's dedication to human space flight and exploration, and to take on the hard challenge to live within the tough budget constraints," said Dan Dumbacher, a deputy associate administrator for the space agency.

In August, ATK lost out on a multimillion-dollar contract to use its Liberty rocket system to shuttle cargo and crew to the International Space Station. Instead, contracts went to Boeing Co., Space Exploration Technologies Corp. and Sierra Nevada Corp. ATK officials are evaluating how the company can use its Liberty system for future space travel.

Google+: +Vincent Horiuchi NASA awards ATK new contract

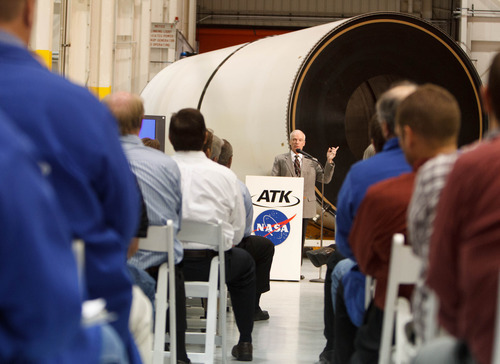

As Alliant Techsystems retools its process of manufacturing booster rockets for NASA's Space Launch System (SLS), it already is looking ahead to the next generation of its rockets.

ATK was awarded a $51 million contract earlier this week to demonstrate new technologies for the next version of its booster rocket for a new launch system.

The boosters will be built from a composite case, and have a new nozzle and higher-performing propellant, said ATK spokeswoman Trina Helquist. The first ground test won't be conducted for a couple of years.

ATK was one of three aeronautical companies awarded NASA contracts totaling $137 million. The other two were e Dynetics Inc. of Huntsville, Ala., and Northrop Grumman Corp. Aerospace Systems of Redondo Beach, Calif.

The new 77-ton launch system will use two five-segment solid rocket boosters similar to those used for the space shuttle, according to NASA.